Gardiner-Aussie Factory, 1920s

Gardiner-Aussie Factory, 1920s

In the boom years of the Country Fire Brigades Board (CFBB) after World War I, motor cars and trucks gradually took the place of horses, but the manual equipment needed replacing.

The Shand Mason and Merryweather manual pumps were large, cumbersome vehicles that needed about 12 people to take it to a fire. When connected to the street mains water, the folding levers were opened and eight to 10 volunteers operated the pump to improve the pressure a little. The brigades relied on local citizens to help do this job.

The CFBB had already started trialling motorised hose carriages to transport firefighters and equipment to calls as early as 1913 (such as Bendigo brigade’s 1912 Commer (also called the Horace Lansell), but very few vehicles had pumps.

TOM GARDINER’S INVENTION

The integration of pumps in vehicles took place in 1925 at Warracknabeal. The process started when the local brigade had an inspection visit from CFBB Chief Officer TS Marshall. After the inspection, the Chief wanted to know whether a small motor could be fitted to a pump or to the old manual engine so that hand levers would no longer be needed.

Captain Tom Gardiner said to the Chief “You are only wasting your money on the obsolete machines. What you want is a motor engine that will get you to the fire quick and also take your equipment, and at the fire have a pump coupled to the water main, and be able to boost up water pressure and be more effective.”

“That is what we are after. Have you anything in mind?” the Chief replied. “Yes, I have,” Tom replied.

The Chief told him to go ahead and let the CFBB know how he was progressing. At the time, Tom was in charge of Melba Picture Theatre, was the local undertaker and was a dab hand at all things mechanical.

The day after talking with the Chief, Tom obtained an old T-model Ford chassis, a pump and some hoses. These were assembled in a big shed at the rear of his house with the help of several men, and Mercer’s Ford Garage helped fix the mechanical parts. They had a friction drive set-up behind the gear box, fitted to a shaft that was connected to the pump at the rear of the vehicle. This was chain driven and it did a good job. From a canvas tank, they were able to get 60 to 70lbs pressure at the gauge on the pump.

However, the chain drive wasn’t successful because it stretched over time and was very noisy. The solution was a pump gearbox fitted to the power take off, just behind the car gearbox, and a more powerful overhead valve engine.

THE FIRST PROTOTYPE

When the first prototype unit had been built, and the pump placed in position, the vehicle was taken to Anzac Park, along with 300 feet of hose. Hoses were laid into the dam and the pump set in action. A small vacuum pump had also been fitted to gain prime. This was friction driven near the pump. As soon as they got the vacuum, the delivery pumps were opened and the water came out of the hose at a fast rate.

The hoses were tested to about 90lbs and the team was pleased with the results. With two hoses on, they achieved about 80lbs running a Y coupling and the pump ran smoothly. The next test used the town’s mains water supply. The pressure in the main was only 25lbs, but when the pump was switched they were able to boost it up to 60lbs quite easily.

They built a square body on the chassis with a brass rail down the centre to hold a ladder and room for eight, seated four on each side. The Officer in Charge and the driver sat in front. Under each footrest was a tray that opened on the outside, and each tray contained 500 feet of flaked hose with a nozzle attached.

When the truck reached the fire, the tray was opened and one firefighter took the branch end to the fire while the other stood by to couple it onto the street main. Then the pump would boost up the pressure delivering to one or two hose lines.

After several tests and the first fire engine completed, the CFBB was notified of its success and Head Station Keeper at Bendigo Fire Station Jack Trengrove was appointed to the position of mechanic. He was required to travel to Warracknabeal to test the pumping machine. He gave it a thorough test using still water and the town supply. He was thrilled with the results and congratulated Tom on his achievement. He believed the new vehicle would improve firefighting.

He reported his results to the CFBB and they decided to hold their annual meeting in Warracknabeal to view the pump.

FULL PRODUCTION BEGINS

Board members were taken to Yarriambiack Creek, which runs through the town, and given a demonstration on still water with four jets of water. Every member of the Board was thrilled the by performance of the machine.

That night the local brigade gave a banquet to honour the CFBB members and the prominent businessmen present. During the evening Board President Mr Wallace announced that the performance of the motor pump was marvellous and the Board had decided to adopt the Gardiner Aussie Fire Engine as a new unit of CFBB. All the units would be built in Warracknabeal.

A new fire station was built for Warracknabeal Fire Brigade and the Gardiner Aussie Fire Engine became well established.

The gearboxes were made by Richardson Gear Company, the pumps by Day Brothers and the couplings by Mann Brothers of Ballarat. The first unit built, a T-model Ford, was delivered to Maryborough Fire Brigade.

The units were built on four types of chassis: Ford, Chevrolet, Graham (Dodge), and REO. The Ford version was for the smaller towns, the Graham and Chevrolet for larger towns, and the big REO 6 was for cities such as Geelong, Ballarat, Bendigo and Warrnambool. More than 50 Gardiner Pumps were built in Warracknabeal until Tom’s death in 1935.

Tom’s family didn’t want to continue manufacturing the trucks, so the CFBB took over the business. CFBB Secretary GJ Sinclair made a change to the pump design and built the Dodge Sinclair (1933 to 1935 models) at Thompsons Foundry in Castlemaine with permission from the Gardiner family. Eventually they built a workshop in Ballarat, with Wally Titherage in charge of the staff.

Following the establishment of CFA in 1944, design work began on the first custom built tanker. In 1947 the first tanker, nicknamed ‘The Firefighter’, was built using an Austin K2 chassis with a

300-gallon (1,135-litre) water tank. The first CFA pumper was built on an Austin Loadstar two-ton chassis in 1952 with a 350 gallons/minute (1,325 litres/minute) pump.

CFA firefighting trucks have come a long way, but we should remember the pioneering work of Tom Gardiner which led to our early motorised pumps.

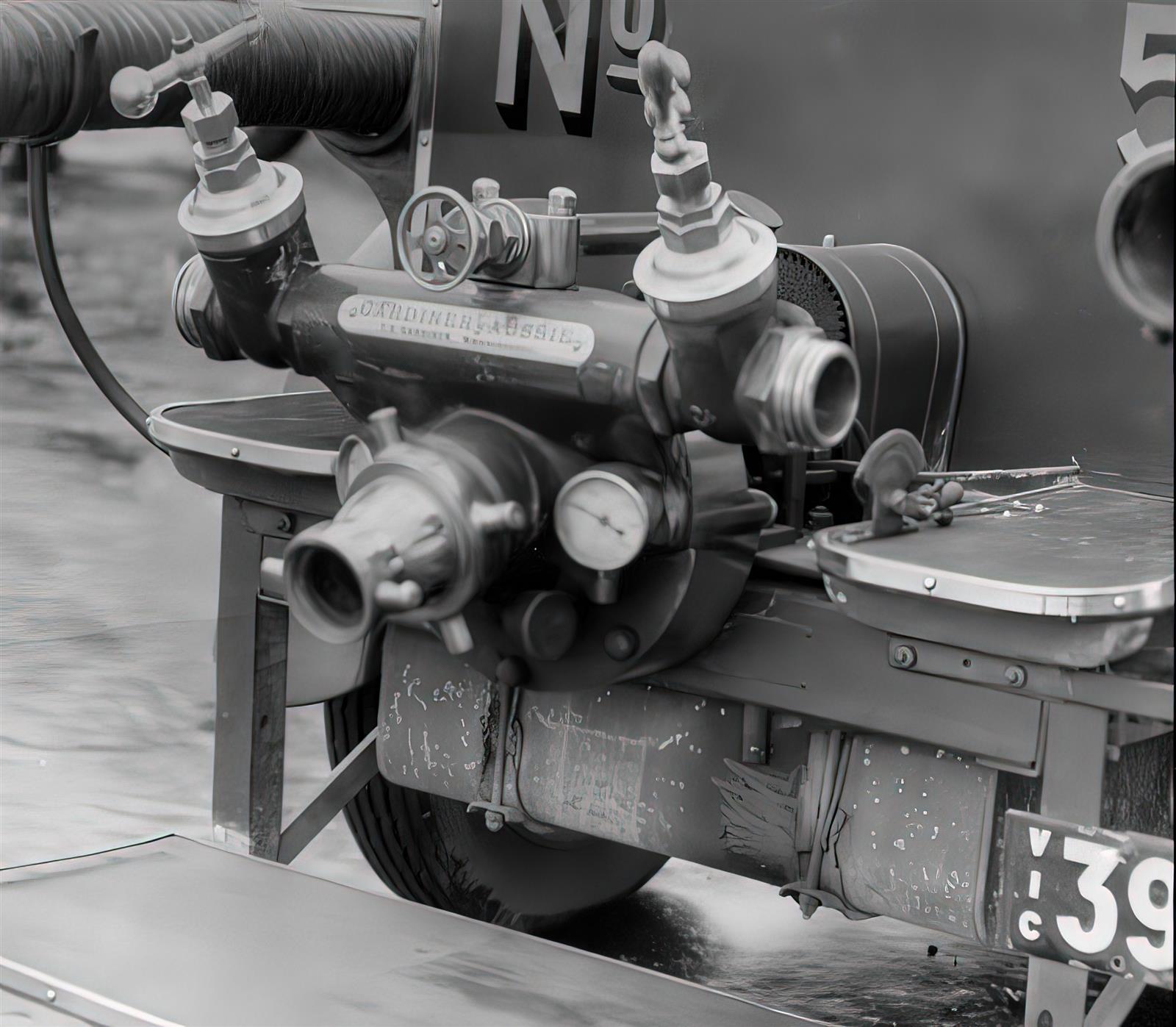

Gardiner pump

Gardiner pump-

REO 6 pumper. L-R in front of pumper: Captain Tom Gardiner, Mechanic Jack Trengrove and Chief Officer W. Chellew

REO 6 pumper. L-R in front of pumper: Captain Tom Gardiner, Mechanic Jack Trengrove and Chief Officer W. Chellew

-

1935 Dodge Sinclair

1935 Dodge Sinclair

-

-

| Submitted by |

News and Media |